Common power factor (PF) ratings range from 0.70 to 0.98. The power factor is also given as a decimal fraction and may be any number less than one. When using the percent efficiency in a math formula, it must be used as a decimal fraction. The efficiency rating may be given as a percent such as 86 percent, or the same percentage may be listed as a decimal fraction like 0.86. Generally higher efficiency motors are those that use more metal in their construction and the metal is laminated and insulated between laminations to reduce eddy currents, which create heat. If the efficiency is not given, it can still be determined using basic math. Motors that fail to state their efficiency probably have poor efficiency ratings. The rated percent efficiency for the motor is listed on most motors but not all. The LRA rating of a motor is the most amperage the motor can draw under any condition. It would not be correct to say the motor has a locked rotor. If a motor has bad bearings and cannot start, the proper terminology for that condition is to say the motor has stuck or frozen bearings. This is normal on a motor that is off and ready to start. A rotor is said to be locked anytime the rotor is not rotating. This amperage is the current the motor will draw when the motor is started and when the motor is attempting to start and run but is unable to do so for some reason such as mechanically stuck bearings. Measuring the actual motor amperage and comparing it to the FLA is a good way to quickly tell if a motor is overloaded. The motor will draw more than the rated FLA when it attempts to operate at more than the rated horsepower. The motor will draw less than the listed FLA if the motor is operating at less than the rated horsepower. This amperage is the current the motor will draw when the motor is loaded up to its rated horsepower. The motor may be operated at any voltage within 10 percent of the design voltage. The voltage listed on the data plate is the design voltage the motor was made for.

#Motor winding calculation code#

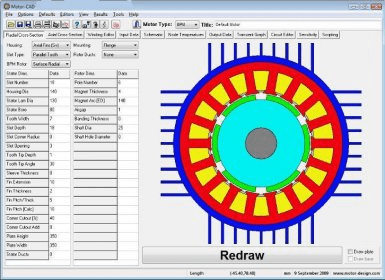

In this moment, there is only the possibility of selling the source code with all rights for future sale. However, if you are interested in purchasing this unique program in future, please submit your contact data ( no any obligations ) using contact form. We want to mention that the program for itself is not for sale at this moment. It gives a complete internal connection diagram also. Our program is not just a " wire" calculator.

In that way, mistakes will be avoided if the data of base winding are not reliable. In the case of redesign (change of voltage, frequency, poles, span, circuits, connection, phases etc) is always good to do a double check using this core calculation. It is not limited to only two layer, standard lap winding, but gives all the calculations for single/double/mixed layer, even unbalanced, interleaved, interspersed, winding etc, concentric or lap.

#Motor winding calculation software#

Compared to similar software for the motor design/redesign in rewind shops, our program is much more comprehensive, because it provides everything you need in motor repairing. Our intent is to show you briefly some of capabilities of our useful and user-friendly software with which we do our calculations. Some screenshots are intentionally omitted. Some screenshots from our program for core-calculation of winding data for three-phase induction motors ( English version) are presented here.

0 kommentar(er)

0 kommentar(er)